In the field of silicone product manufacturing, the journey from mold design to mass production is fraught with challenges. A single misstep can lead to budget overruns, delivery delays, or even quality issues. As a professional silicone product manufacturer, we understand how crucial cost control is for our clients. This article reveals five common cost traps to help you make informed decisions when choosing a manufacturing partner.

Table of Contents

TogglePoor Mold Design Leading to High Modification Costs

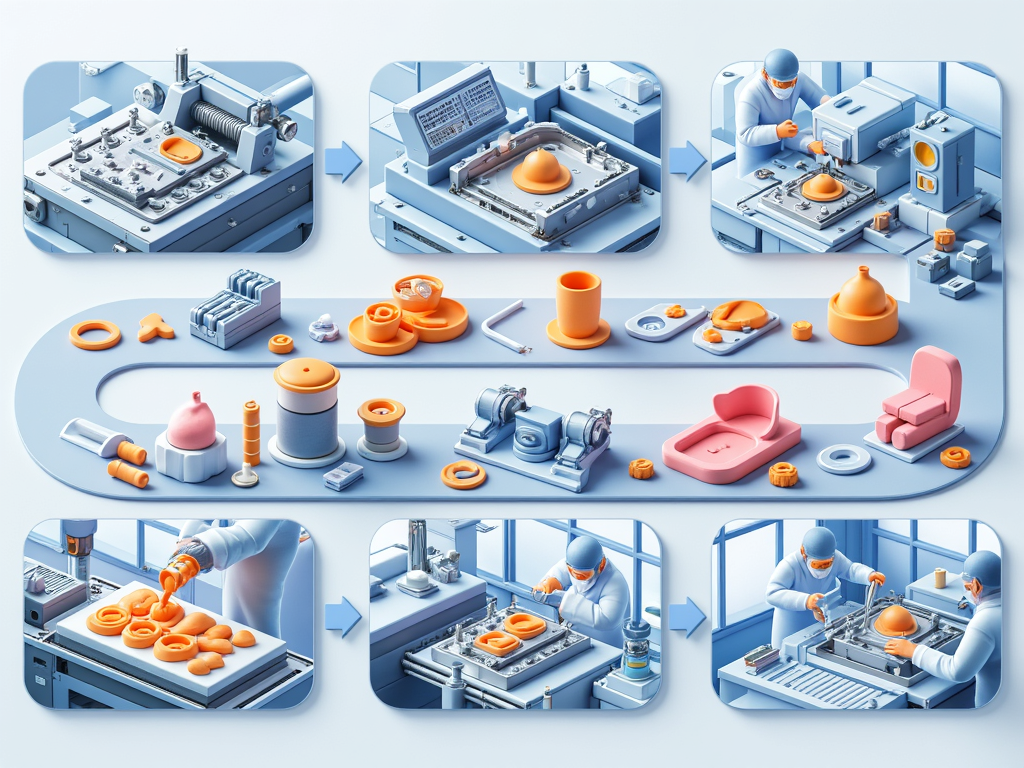

Molds are the core of silicone product manufacturing, yet many clients underestimate the importance of upfront design. Issues like improper parting lines, incorrect draft angles, or uneven wall thickness can lead to repeated mold modifications, increasing costs by over 30%. Professional manufacturers provide DFM (Design for Manufacturing) analysis to optimize product structure and avoid costly late-stage adjustments.

Material Selection Mistakes Resulting in Hidden Costs

Silicone materials vary widely in hardness, temperature resistance, tear strength, and other properties. Choosing the wrong material can lead to subpar performance or even batch rejection. Experienced manufacturers recommend the most cost-effective materials based on application (medical-grade, food-grade, or industrial-grade) to avoid scrap risks.

Inefficient Production Process Selection

Silicone products can be made using compression molding, injection molding, or liquid silicone rubber (LSR) molding. Selecting the wrong process can reduce efficiency and yield. For example, complex structures made via traditional compression molding instead of LSR may increase production time by 50%. A skilled manufacturer matches the best process to product requirements for optimal efficiency and quality.

Overlooking Secondary Processing Costs

Many silicone products require post-processing like printing, laser engraving, bonding, or assembly. Failing to plan for these steps upfront can lead to extra logistics, storage, and management expenses. A full-service manufacturer provides end-to-end solutions—from molding to finishing—reducing intermediate costs.

Quality Control Failures During Mass Production

Quality fluctuations in mass production are among the biggest hidden cost traps. Without strict IPQC (In-Process Quality Control), defective batches can waste materials, labor, and time. Top-tier manufacturers implement full-process quality systems, including first-article inspection, in-process checks, and final testing to ensure consistency.

Why Choose Us as Your Silicone Product Manufacturer?

- 15+ Years of Expertise: Serving 500+ clients with professional silicone solutions

- One-Stop Service: Comprehensive support from design optimization to mass production

- Precision Testing Equipment: CMMs, tensile testers, and more for guaranteed quality

- Transparent Pricing: No hidden fees—just accurate cost control for your project

If you’re looking for a reliable silicone product manufacturer, contact us today for a free consultation and samples. Our expertise and cost-optimized solutions will ensure a smooth journey from design to delivery.

Take Action Now: Visit our website or call +86 13622305623 for a customized silicone manufacturing solution!